EOT Crane Spare Parts

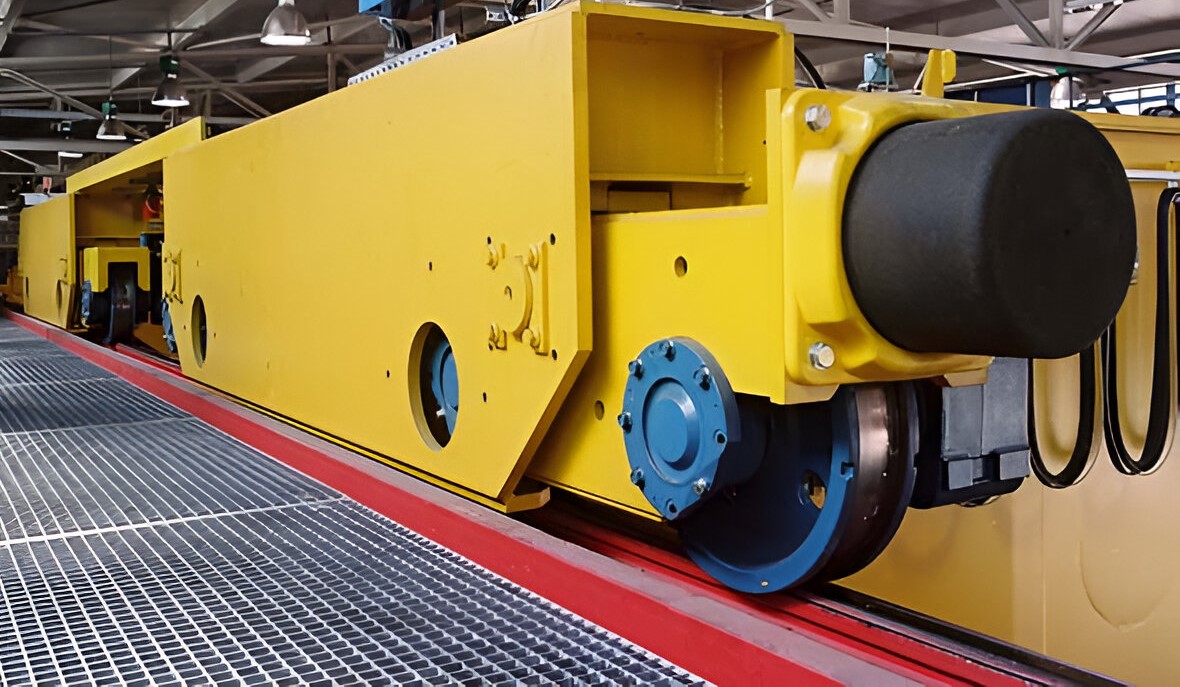

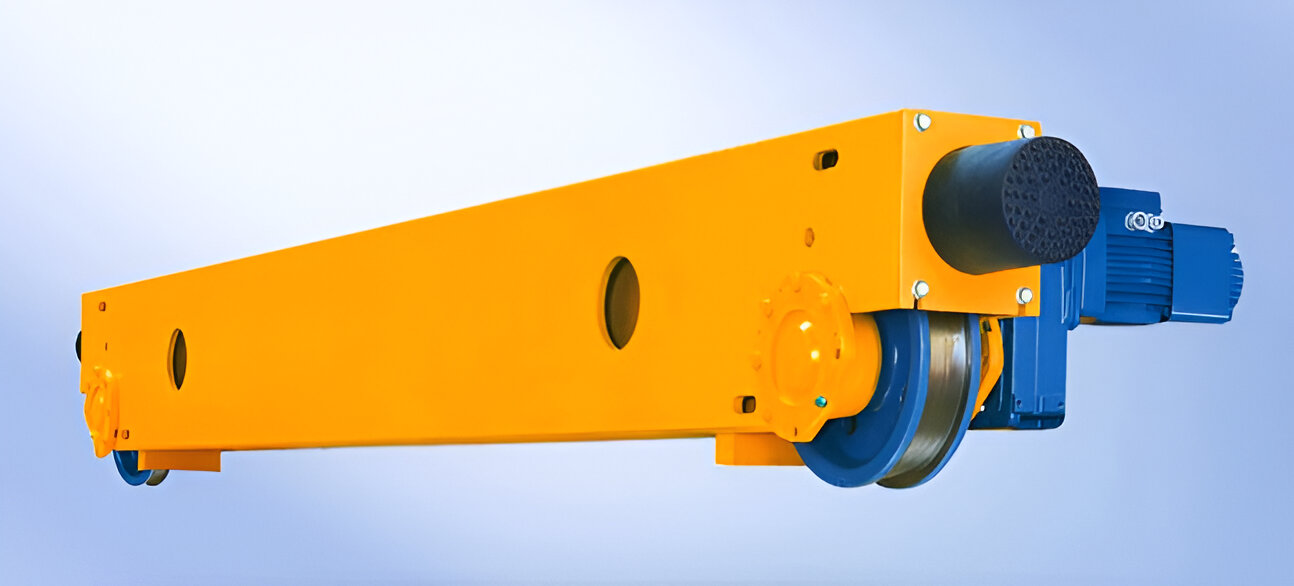

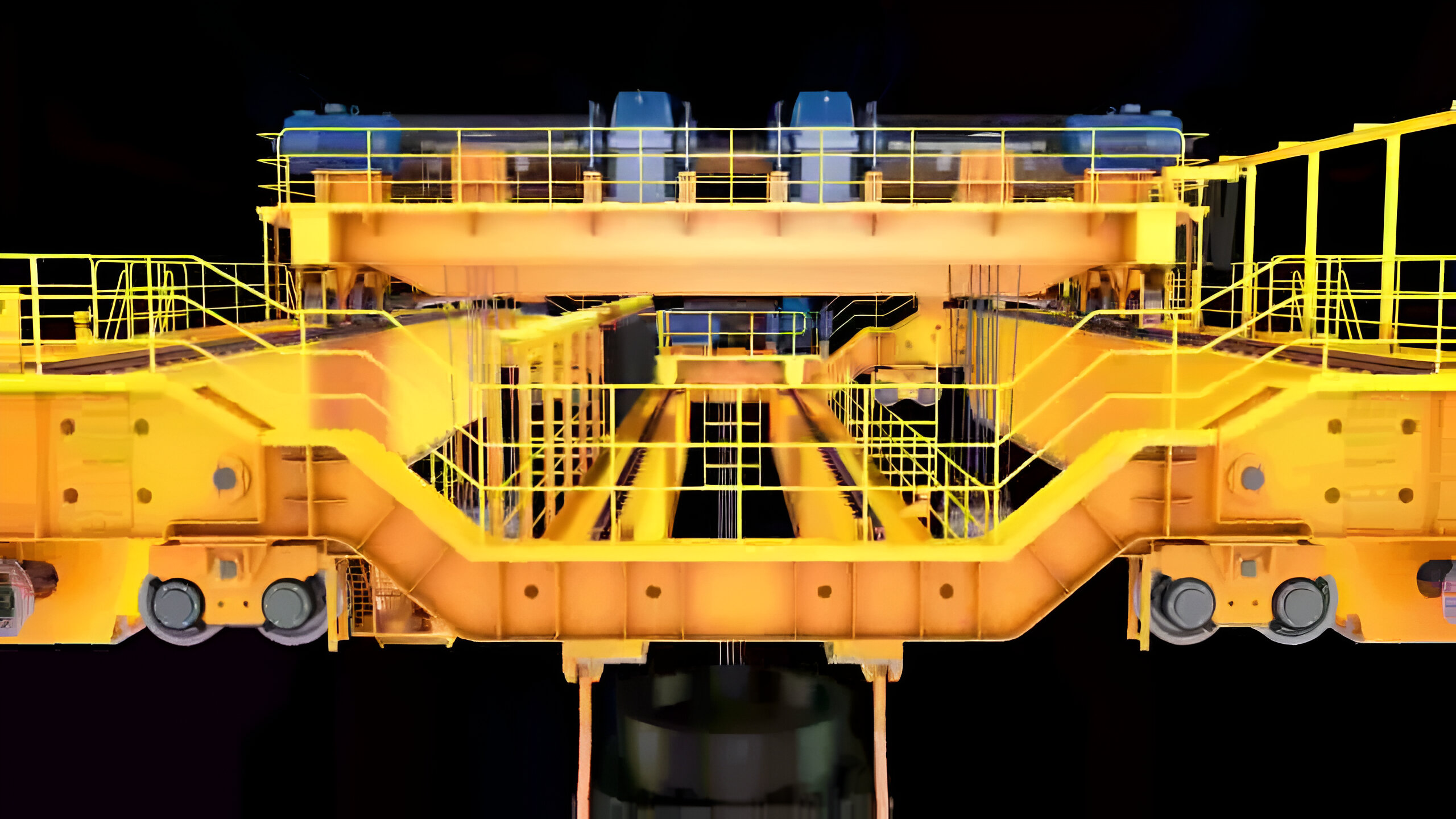

End Carriages are vital components of Electric Overhead Travel (EOT) Cranes, serving as the outermost framework that supports the entire crane structure. These sturdy assemblies house the wheels and motors responsible for the crane's lateral movement along the runway beams. End Carriages ensure smooth and precise travel, facilitating efficient material handling operations in industrial settings. Built to withstand heavy loads and constant movement, they play a crucial role in maintaining the stability and reliability of EOT Crane systems.

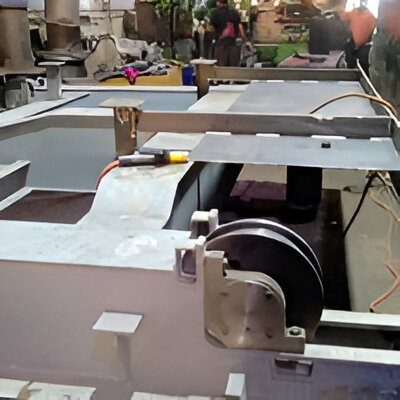

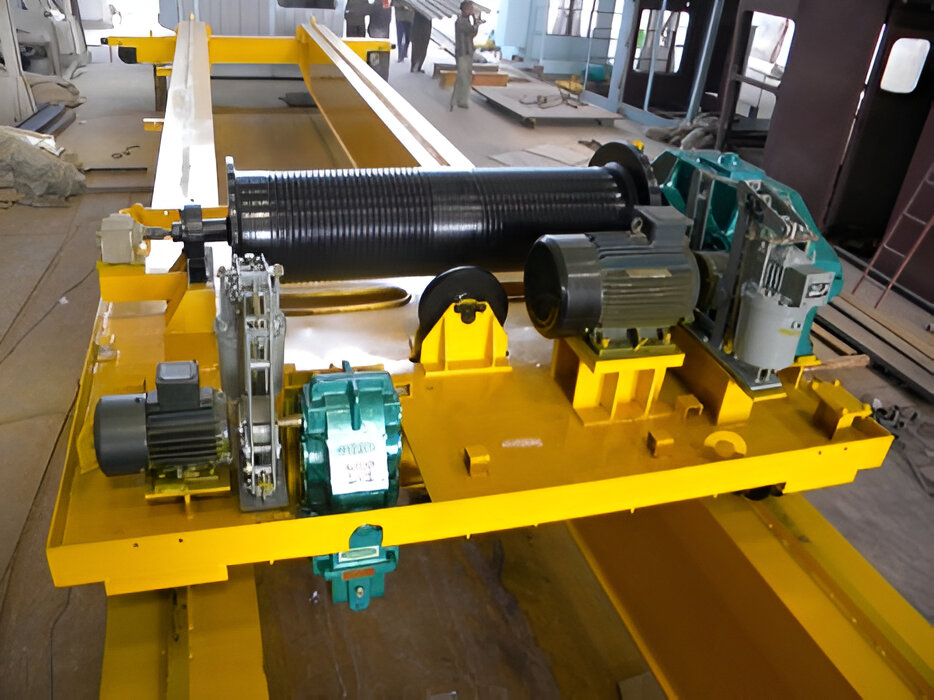

The Crab Assembly is a pivotal component within Electric Overhead Travel (EOT) Cranes, responsible for enabling the crane's hoisting and traversing functions. Comprising a robust framework housing the hoist motor, gearbox, and rope drum, the Crab Assembly ensures precise vertical lifting and horizontal movement of loads. With its sturdy construction and precision engineering, the Crab Assembly guarantees smooth and efficient material handling operations in various industrial environments. Designed for durability and reliability, it plays a crucial role in maximizing the performance and uptime of EOT Crane systems.

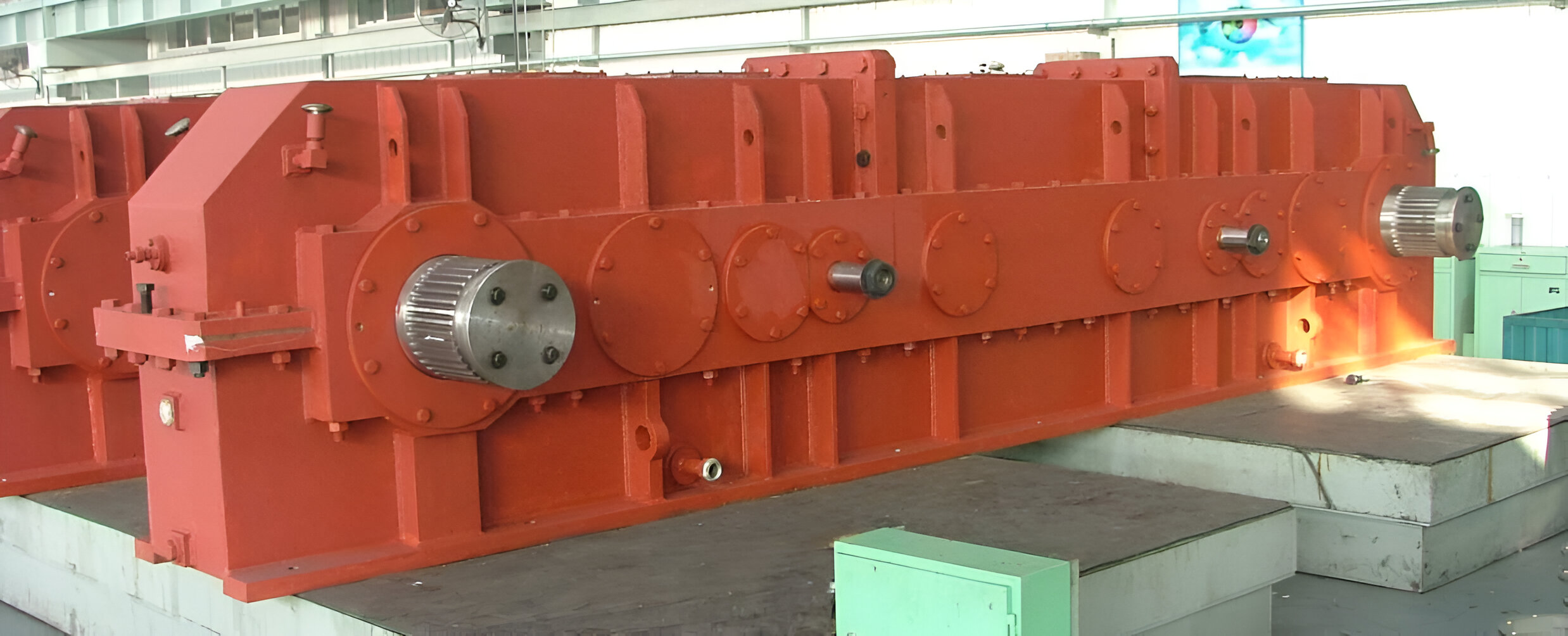

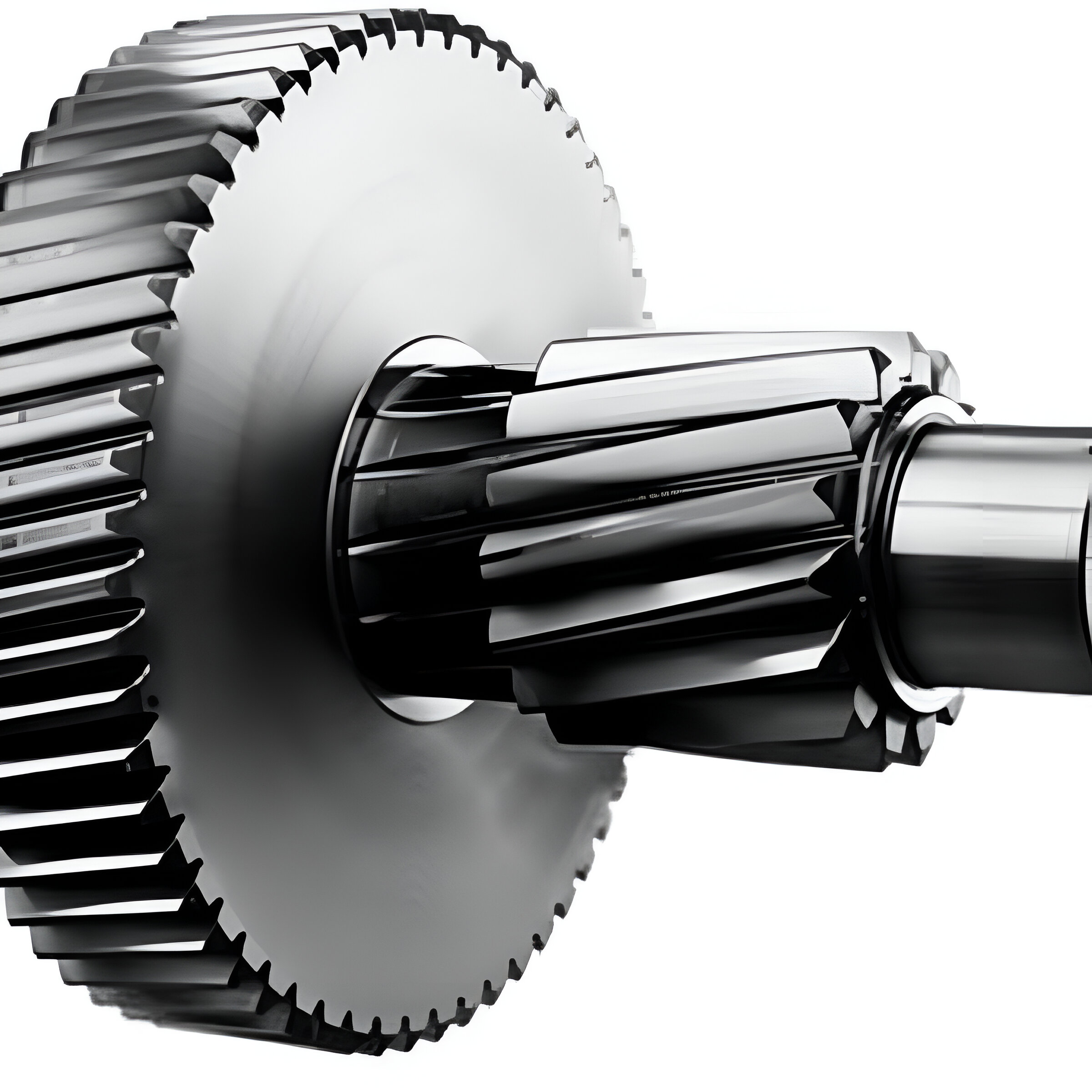

The Gearbox is a critical component in Electric Overhead Travel (EOT) Cranes, responsible for transmitting power from the motor to the wheels or drums, enabling smooth and controlled movement. This essential assembly consists of gears and shafts meticulously designed to regulate the speed and torque required for lifting and traversing operations. With its robust construction and precise gearing, the Gearbox ensures optimal performance and efficiency of the crane system, contributing to seamless material handling operations in industrial environments. Trusted for its durability and reliability, the Gearbox plays a crucial role in maintaining the productivity and safety of EOT Crane operations.

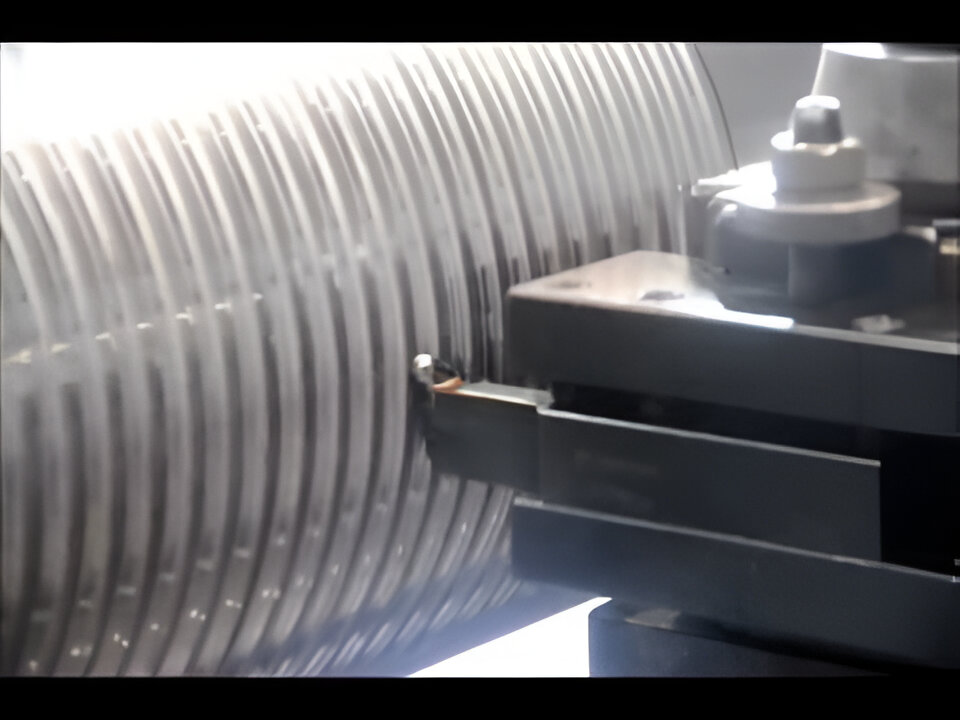

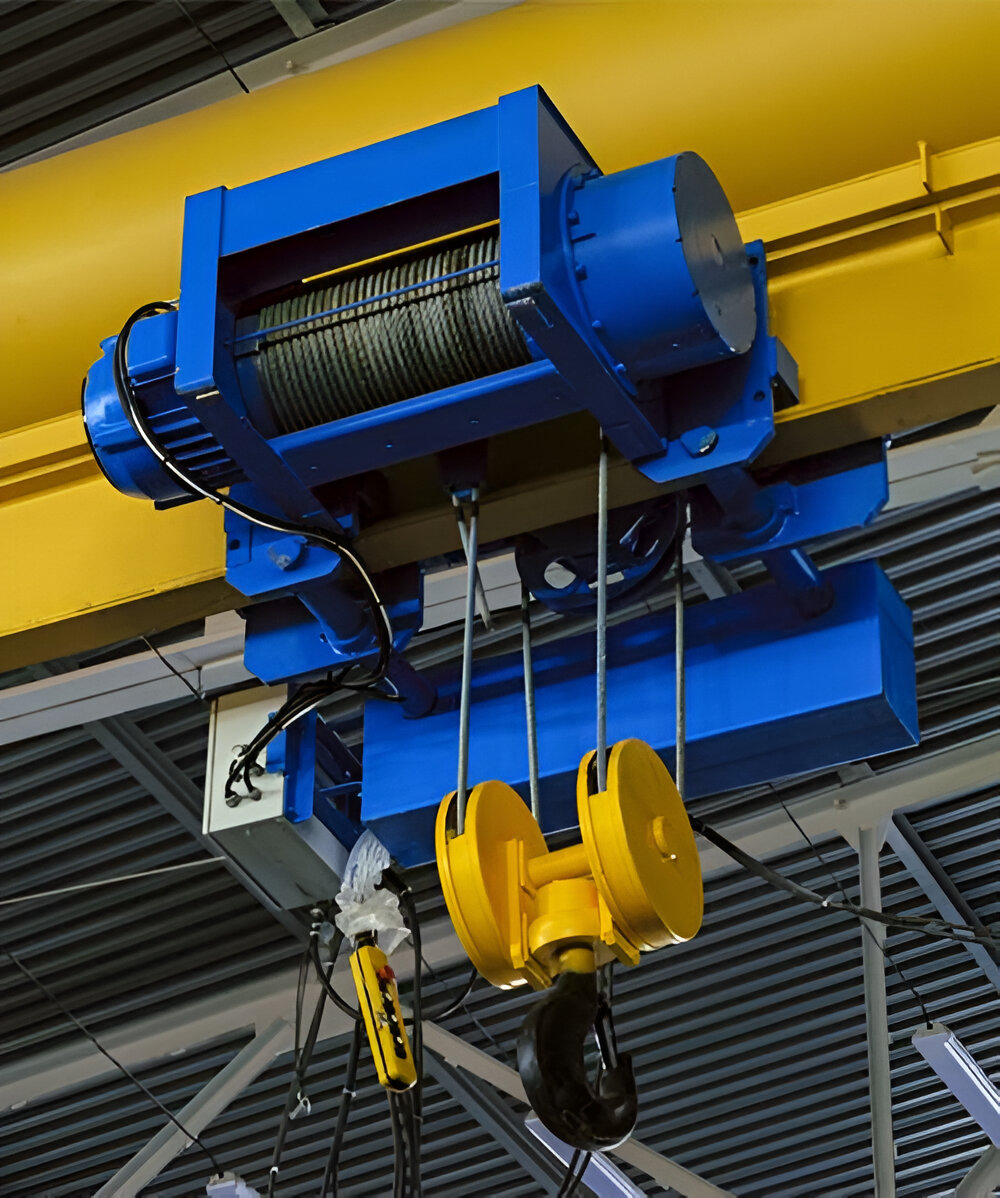

The Rope Drum is a fundamental component of Electric Overhead Travel (EOT) Cranes, serving as the primary mechanism for lifting and lowering loads. This cylindrical drum, typically mounted on the hoist mechanism, winds and unwinds the lifting rope or wire rope during vertical movement. Its precise construction and smooth operation ensure efficient and controlled lifting, contributing to safe and reliable material handling in industrial settings. Designed to withstand heavy loads and constant use, the Rope Drum plays a crucial role in the overall performance and productivity of EOT Crane systems, making it an essential spare part for maintenance and repair needs.

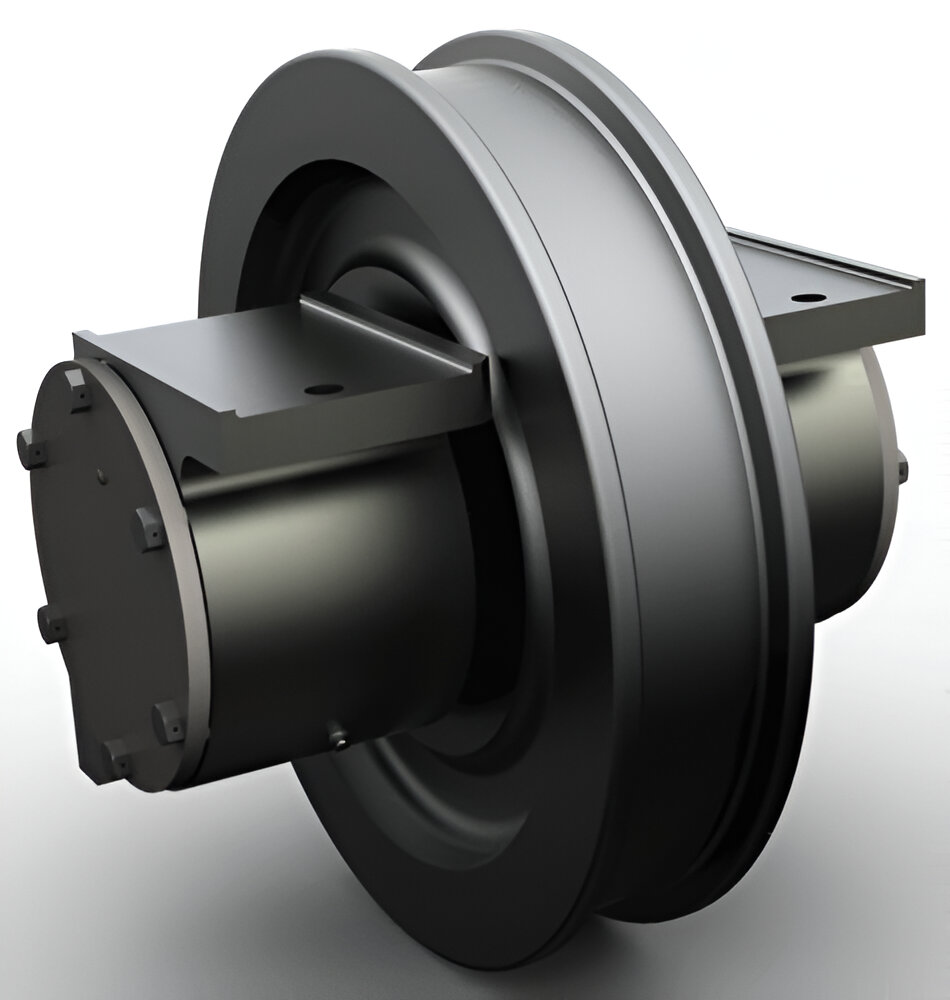

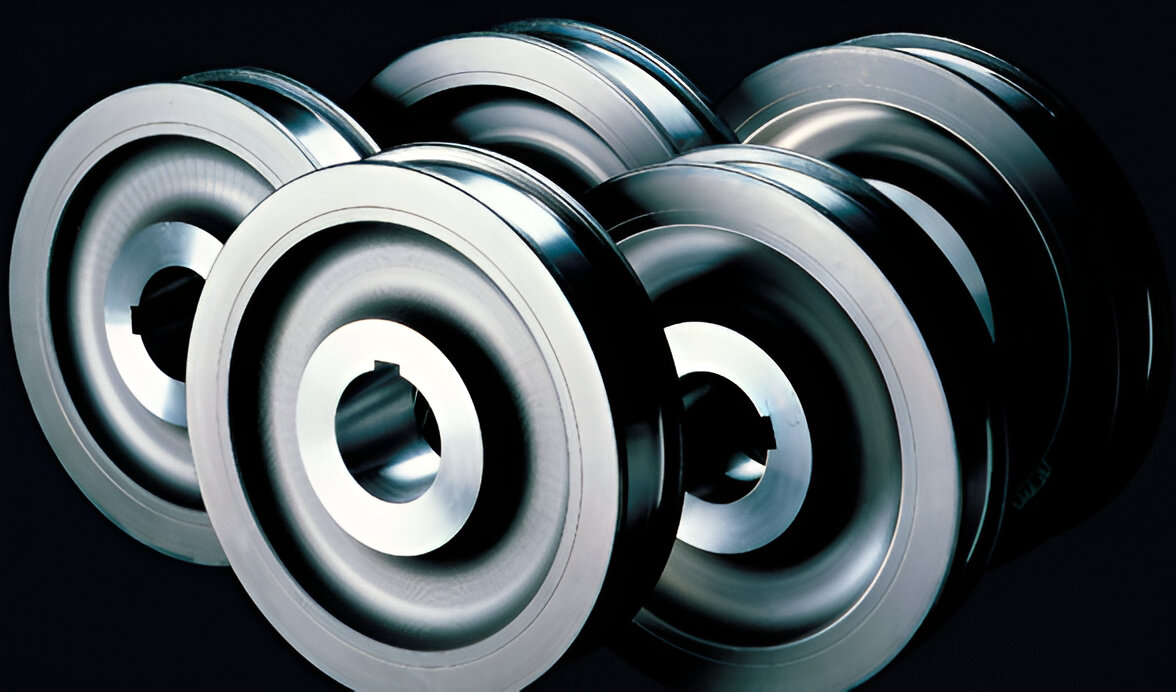

Crane Wheels are integral components of Electric Overhead Travel (EOT) Cranes, providing essential support and mobility along the runway beams. These rugged wheels, typically made of forged steel or cast iron, are mounted on axles and designed to traverse along the crane rails with precision and stability. Their durable construction and precise machining ensure smooth and efficient movement of the crane along the runway, facilitating seamless material handling operations. Engineered to withstand heavy loads and repetitive motion, Crane Wheels play a crucial role in maintaining the reliability and performance of EOT Crane systems, making them indispensable spare parts for maintenance and replacement purposes.

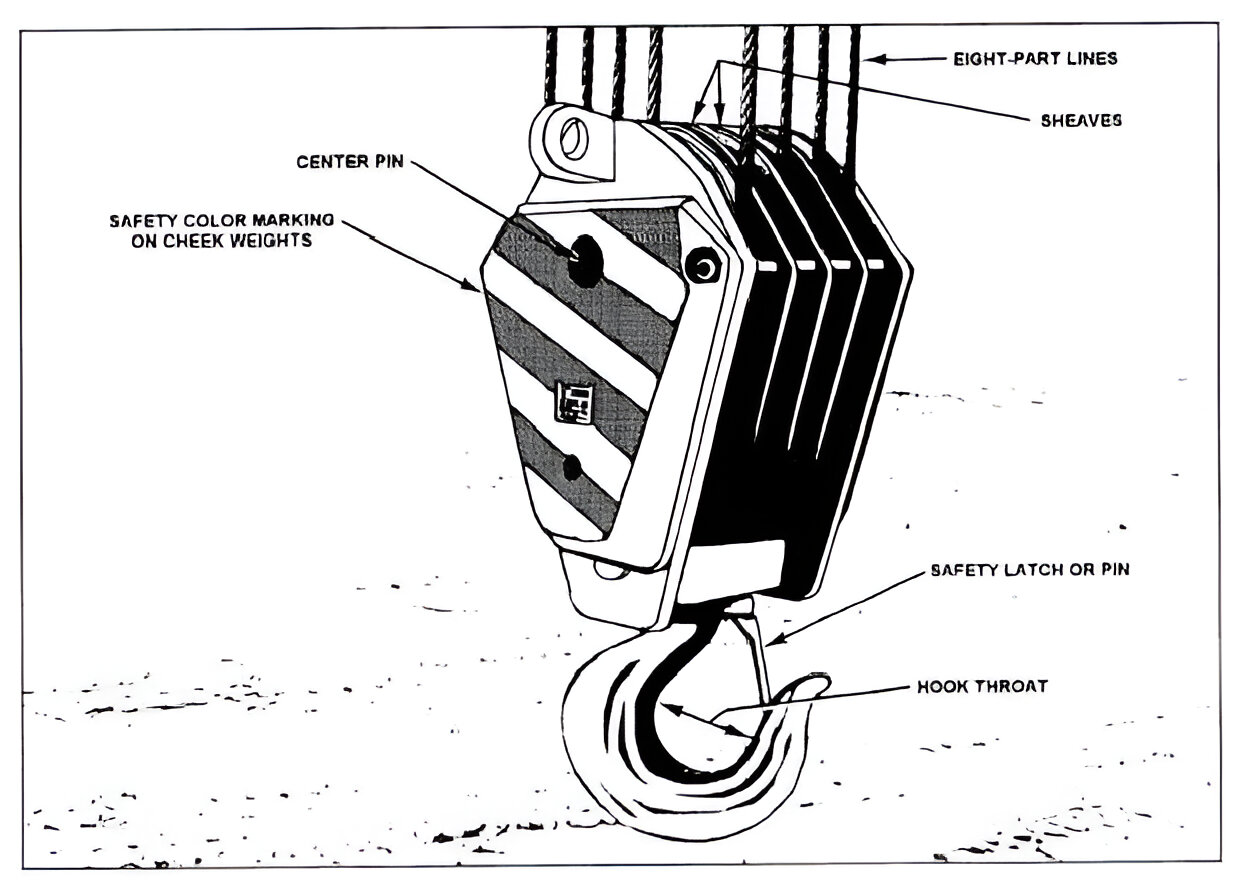

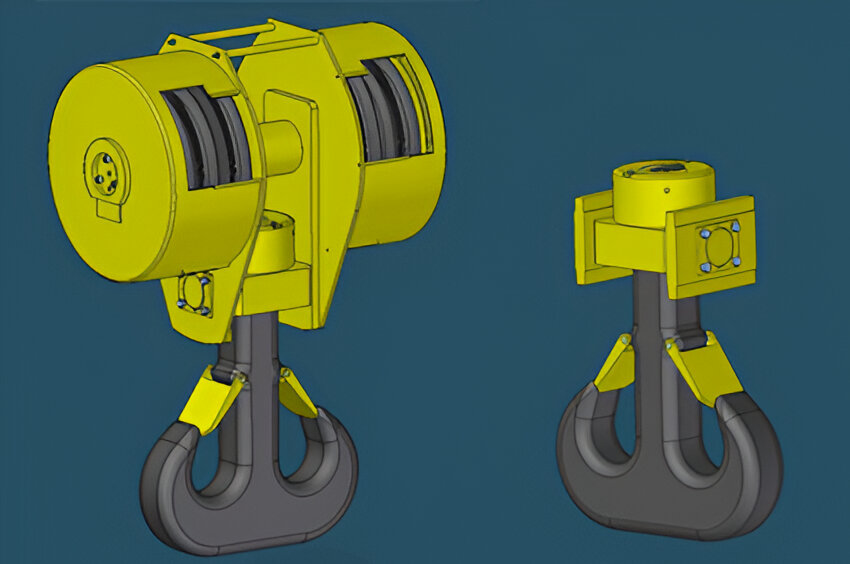

The Bottom Block, also known as the bottom pulley block or the lower hook block, is a key component in Electric Overhead Travel (EOT) Cranes, responsible for supporting and guiding the load during lifting and lowering operations. This robust assembly consists of a pulley or sheave mounted within a sturdy frame, through which the lifting rope or wire rope passes. The Bottom Block ensures smooth and controlled movement of the load, distributing the weight evenly and minimizing friction during lifting and lowering processes. Engineered for durability and precision, it plays a crucial role in facilitating safe and efficient material handling operations in industrial environments. As a vital spare part, the Bottom Block is essential for maintaining the reliability and performance of EOT Crane systems.

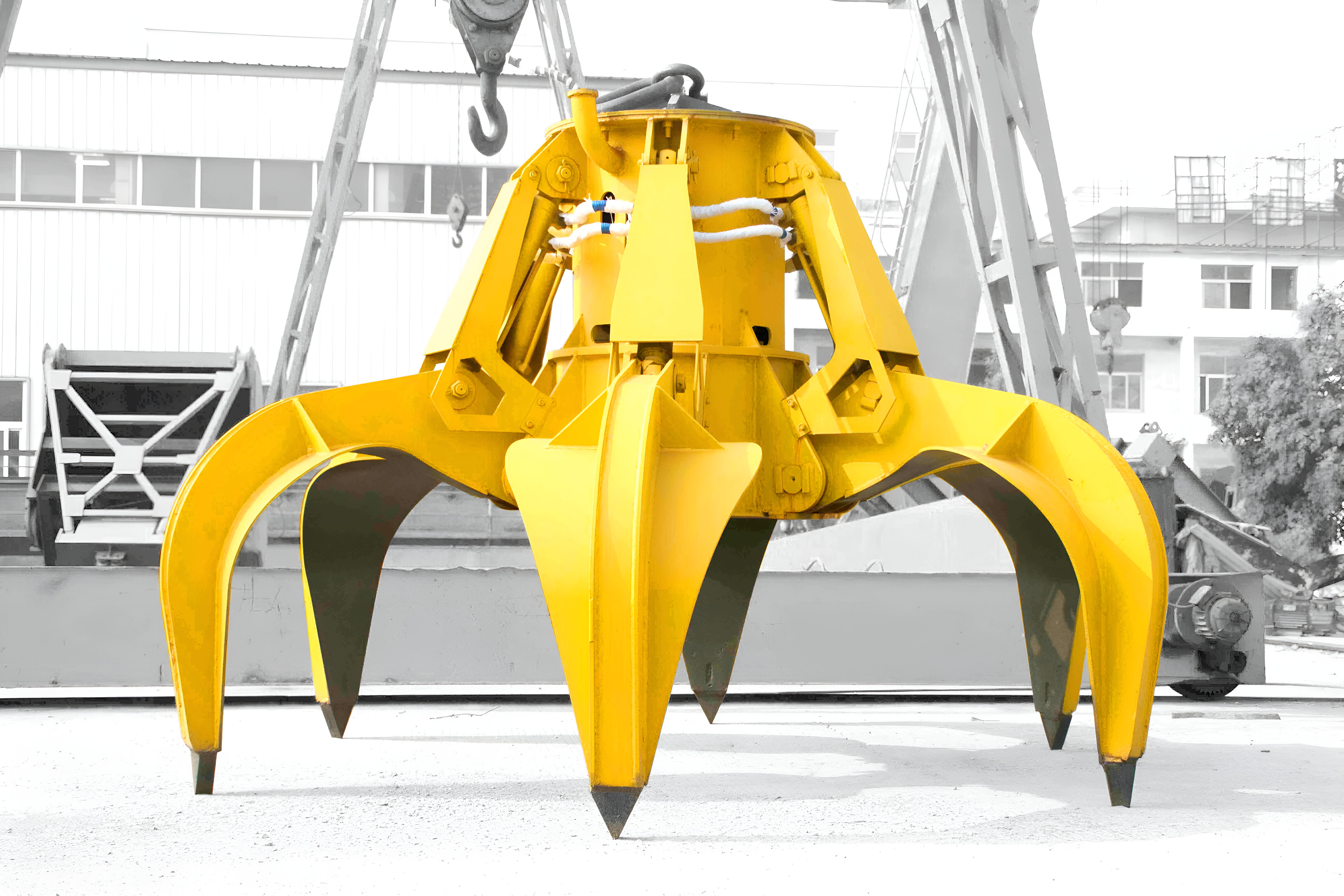

The Grab Bucket is a specialized attachment used in Electric Overhead Travel (EOT) Cranes for handling bulk materials such as sand, gravel, or scrap metal. This versatile device features a hinged or clamshell-like design, allowing it to open and close to grab and release materials as needed. Equipped with robust jaws or claws, the Grab Bucket securely grasps the material during loading and unloading operations, ensuring efficient and precise material handling. With its rugged construction and hydraulic or mechanical operation, the Grab Bucket enables crane operators to tackle a wide range of material handling tasks with ease and precision. The Grab Bucket is an essential spare part for EOT Crane systems operating in industries such as construction, mining, and waste management.

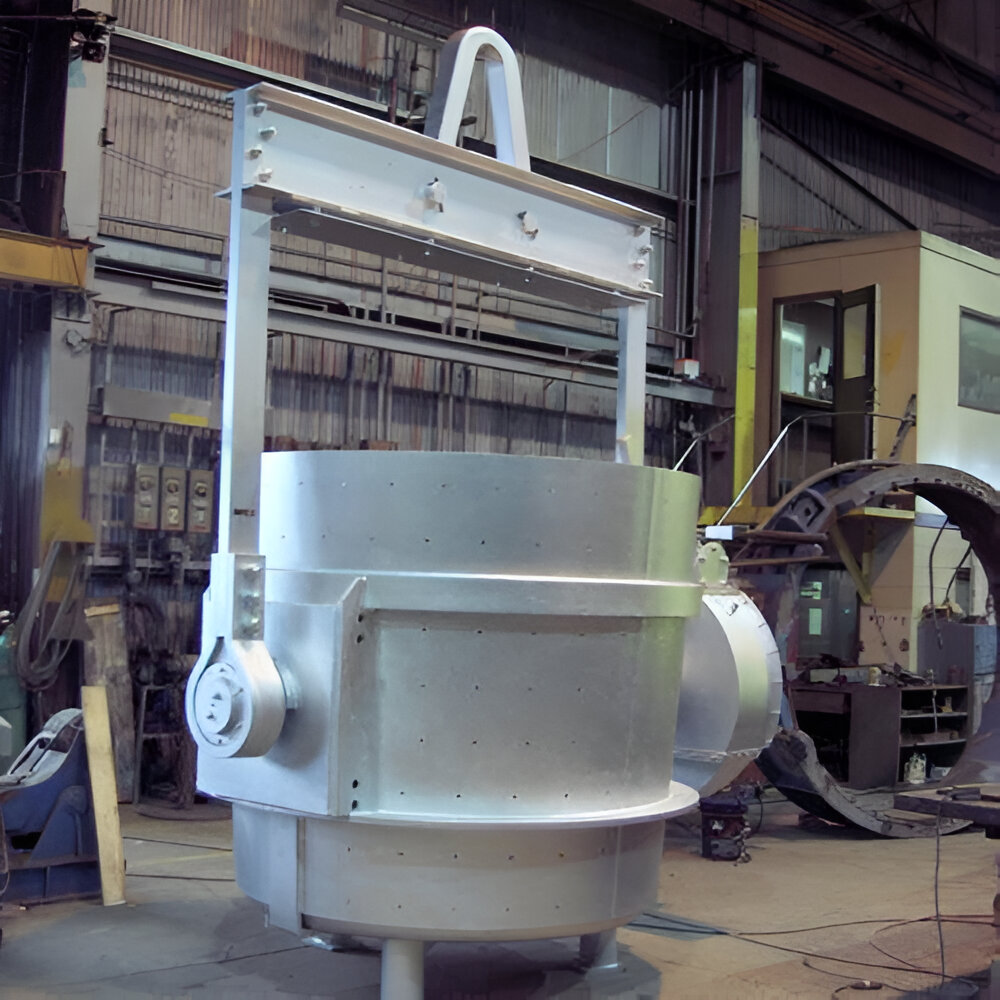

Ladles are specialized containers used in Electric Overhead Travel (EOT) Cranes for transporting and pouring molten metal in steel mills and foundries. These robust vessels are typically made of refractory materials capable of withstanding extreme temperatures and corrosive environments. Ladles feature a durable handle for maneuvering and pouring, along with a spout or lip for controlled pouring of molten metal into molds or other processing equipment. With their precise engineering and heat-resistant construction, Ladles ensure safe and efficient handling of molten metal, minimizing the risk of accidents and material loss during the casting process.Ladles are essential components of EOT Crane systems in steelmaking and metallurgical industries.

Explore our comprehensive company brochure and discover our wide range of Products, Services & expertise.

Single Girder EOT Crane

An ideal solution for light-duty and medium-duty material handling. Mainly consisted of one main crane girder, supported on each side by an end truck, with a monorail trolley hoist suspended on the beam girder, these are the most cost-effective overhead bridge crane solutions for various workshops and industrial applications.

Double Girder EOT Cranes

An optimal choice for heavy-duty material handling tasks, Offering robust support and enhanced stability, they deliver superior lifting capabilities, making them ideal for demanding industrial environments and workshops. Offering unparalleled strength and reliability, they are the preferred solution for efficiently managing heavier loads and maximizing productivity.

Ladel Cranes

Designed for specialized material handling in steel mills and foundries, these are engineered to meet the rigorous demands of molten metal handling. Featuring a sturdy construction, these cranes are equipped with a ladle hook or gripping mechanism for securely transporting. They offer precise control and robust safety features.